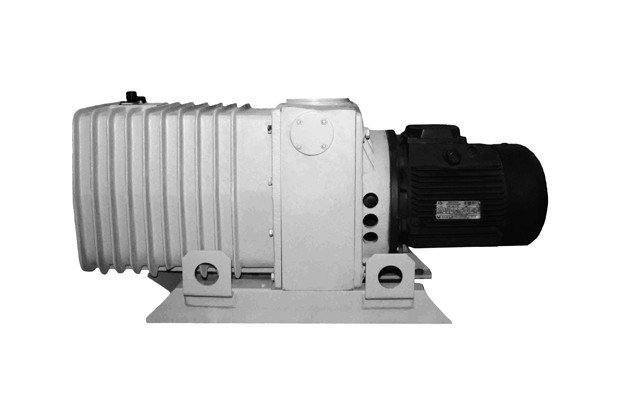

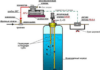

ВАКУУМНЫЕ НАСОСЫ

ВАКУУМНЫЕ СИСТЕМЫ

ВОХДУХОДУВКИ

Промышленный тип турбовоздуходувки и воздуходувки

Турбовоздуходувки представлены весьма известными приборами в многочисленных секторах экономики работы человека. Данное затрагивает как изготовление различных элементов, так и снабжение нужными обстоятельствами искусственных водоемов,...

Все про гидрикс воздуходувки

Предприятие «Гидрикс» представляется технологическим производственным предприятием, что начало собственную активность в 2010 году, как отделение холдинговой компании «Эко-Потенциал», развивая инженерно-конструкторские и производственные технологии. Данная...

Газодувка и ее основные параметры

Скорость работы и производительность газодувок выдвигают их на первый план среди подобных типов компрессоров, которые пользуются внешним типом сжатия. В основе принципа работы лежит...

Воздуходувка в быту и на производстве

Различные модификации промышленных и бытовых воздуходувок являются хорошими помощниками для широкой группы людей, имеющих сад, дачный участок или большую промышленную территорию. Удобные агрегаты являются...